2 min read

Nevatio Engineering opens in Reno

Nevatio Engineering an on-demand Machine Design and Automation Company has opened in Reno.

If you are looking for a...

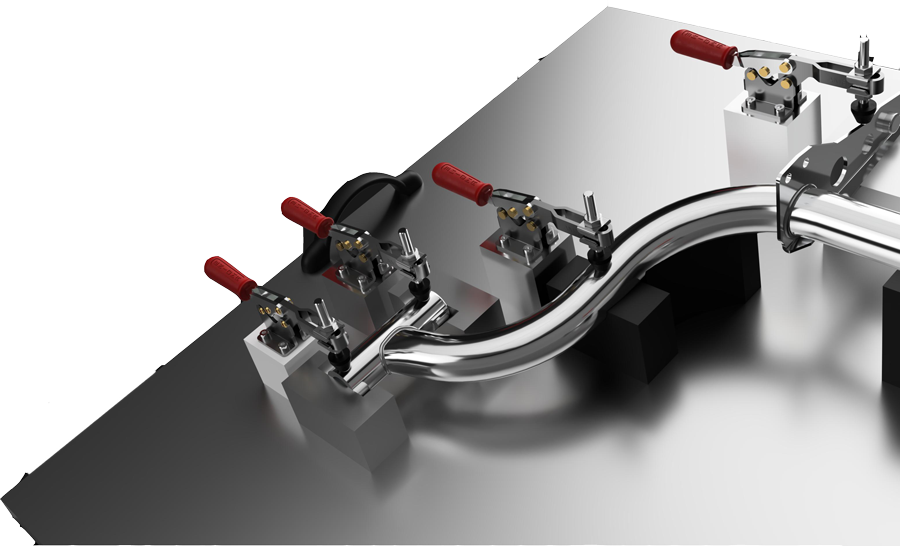

Custom jigs and fixtures provide the stability and repeatability needed for high-volume machining. At Nevatio, our engineers design reusable tools to your exact specifications - helping you speed up production, improve accuracy, and integrate seamlessly into automated systems.

By collaborating directly with your team, we catch issues early and deliver fast, reliable solutions for prototypes, large-scale runs, or industrial automation.

Fixtures play a critical role in the manufacturing process by providing stability for parts that are otherwise difficult to machine, such as sheet metal, castings, or raw material.

When precision CNC fixtures aren’t available in-house, Nevatio’s engineers design and manufacture custom solutions or adapt existing designs to meet your specific production requirements.

.png)

Modern fixture design starts with advanced 3D CAD platforms such as SolidWorks, ProEngineer, and AutoCAD.

At Nevatio, we import your part models and CNC machine layouts directly into the software, allowing us to create fixtures that hold components securely without interfering with surrounding processes. This approach streamlines setup, protects equipment, and ensures your fixtures are production-ready from day one.

.png)

A well-engineered fixture is more than a support tool - it’s an efficiency driver. At Nevatio, we review every design with our manufacturing team to ensure it delivers real results:

• Catch issues early by validating designs before production

• Improve consistency in machining and assembly

• Reduce downtime with tools built for automation

• Enable complex designs using 3D printing when needed

• Scale with demand through adaptable fixture solutions

The result: stronger ROI, smoother production, and a clear path to automation and robotics integration.

Feb 3, 2022 by Nevatio Team

Nevatio Engineering an on-demand Machine Design and Automation Company has opened in Reno.

If you are looking for a...

Oct 7, 2021 by Nevatio Team

Marc specializes in blending rigorous technical skills of mechanical engineering with the elegance of creative design...

Jun 28, 2021 by Nevatio Team

From concept to completion, Nevatio has the skills and creativity to solve the most challenging problems.

Blending...