We believe in being consistent with our deliveries. This means that we are always on time and able to work for your business needs, no matter what they may be.

You may be familiar with CNC machines (or at least have heard about the subject). Similarly, you may also be familiar with the terms "jigs" and "fixtures"...

But, what about CNC fixtures? What exactly are these used for and how do they differ from the ordinary ones?

Let's take a look at all that you need to know about CNC fixtures.

Jigs, fixtures and CNC machining

Jigs and fixtures are often important production floor manufacturing tools that may help minimize costs, improve overall manufacturing quality, automate labor, create efficient workflow procedures, and optimize component assembly.

Fixtures are tools that hold workpieces while they are being cut. Similarly, jigs hold the workpieces and also guide the cutter while cutting. Cutters are guided by jigs, which work in the same way as miter boxes. CNC (Computer Numerical Control) fixtures, on the other hand, don't guide cutters. They simply keep the workpiece secure, supported, and stable while it's being manufactured.

Given the nature of CNC machining, there’s little need for jigs as a g-code guides the cutter, so the term "jigs" is largely related to manual machining.

What exactly is CNC machining?

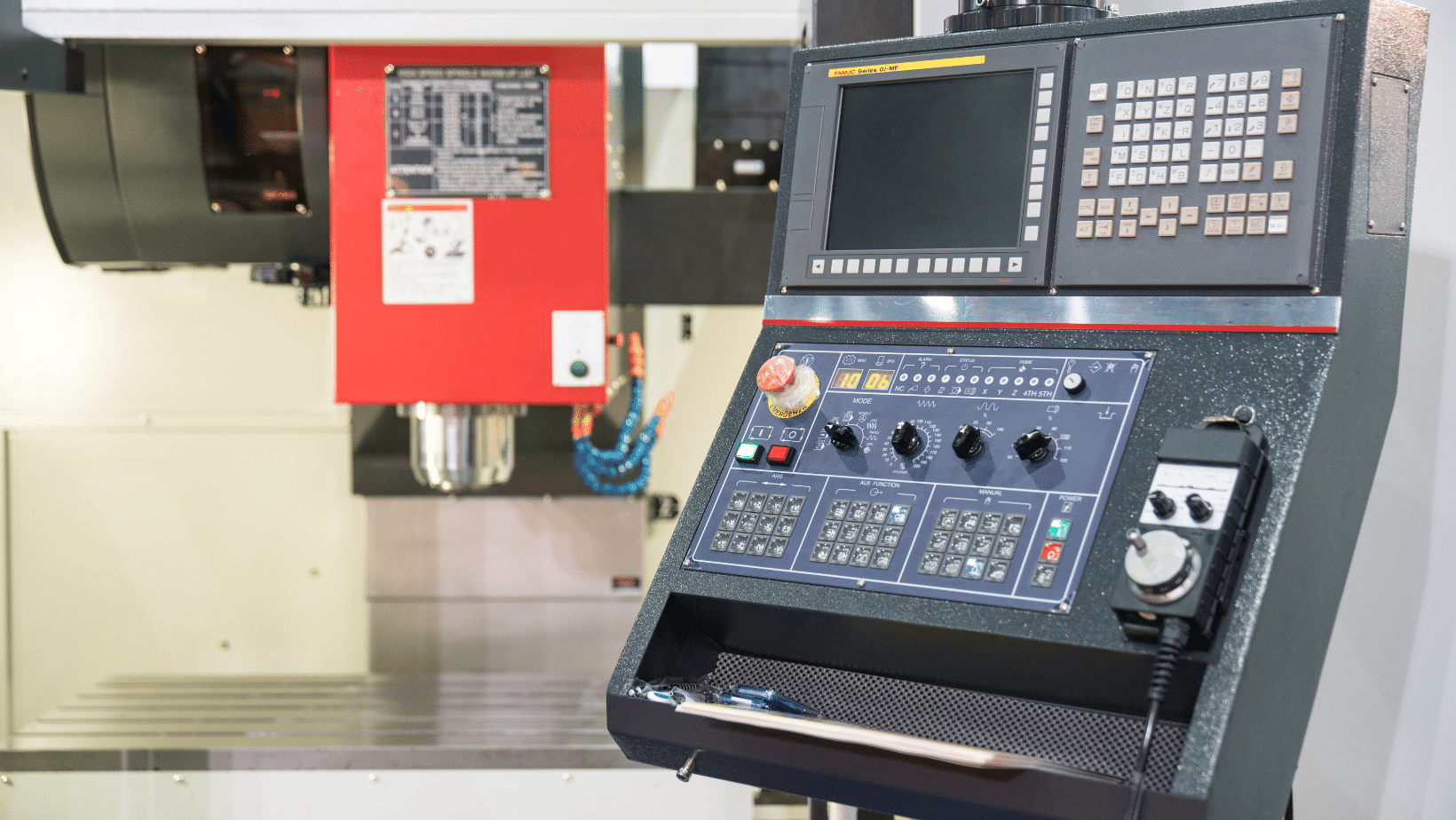

Computer numerical control (CNC) machining is a manufacturing technique in which pre-programmed computer code controls the movement of factory equipment and machinery.

This technology can be used to manage a variety of sophisticated equipment, including grinders and lathes, mills, and CNC routers. Tasks like three-dimensional cutting may be carried out with CNC machining using only one set of instructions.

But, let's go back to CNC fixtures...

What is a CNC Fixture?

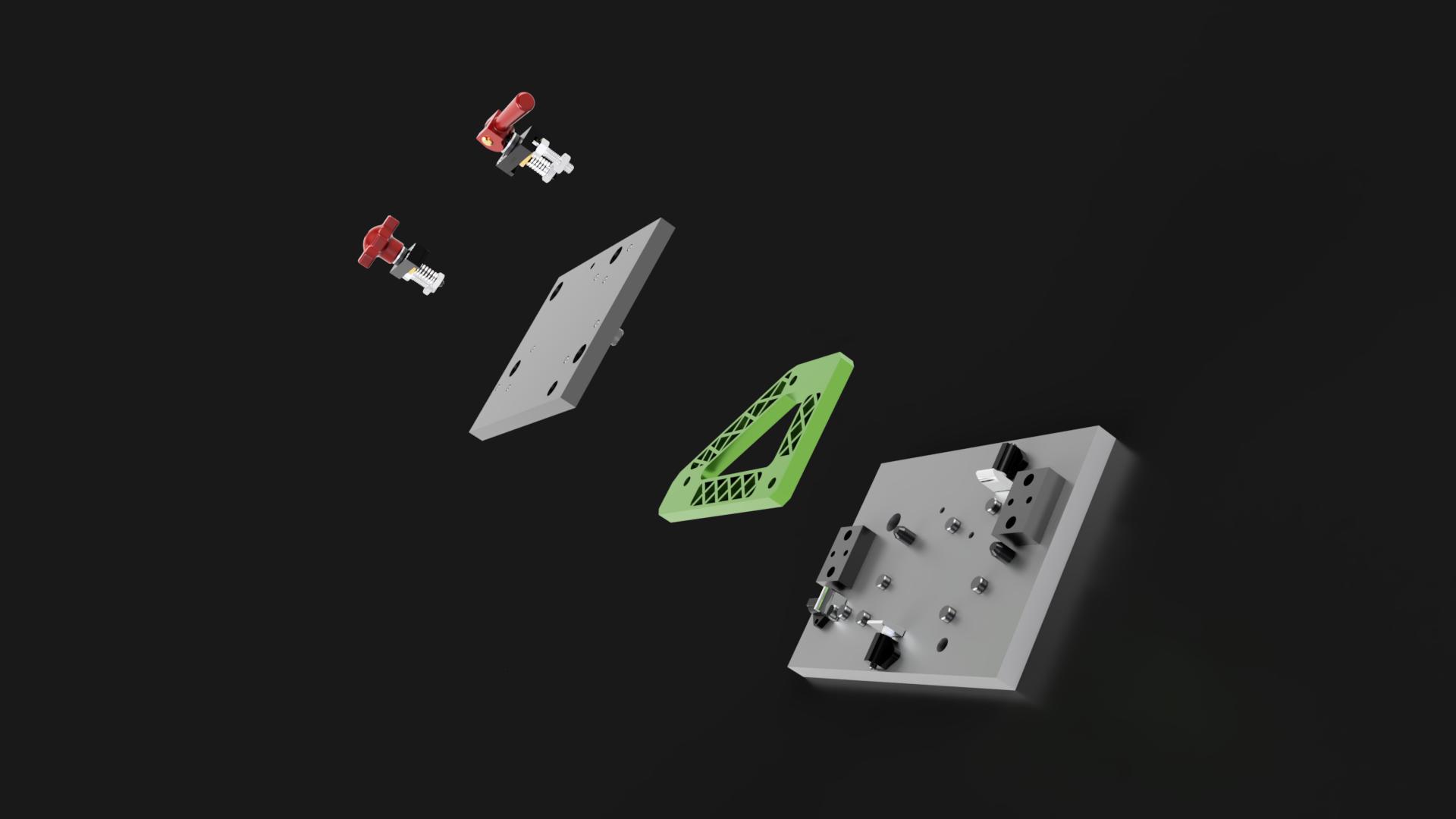

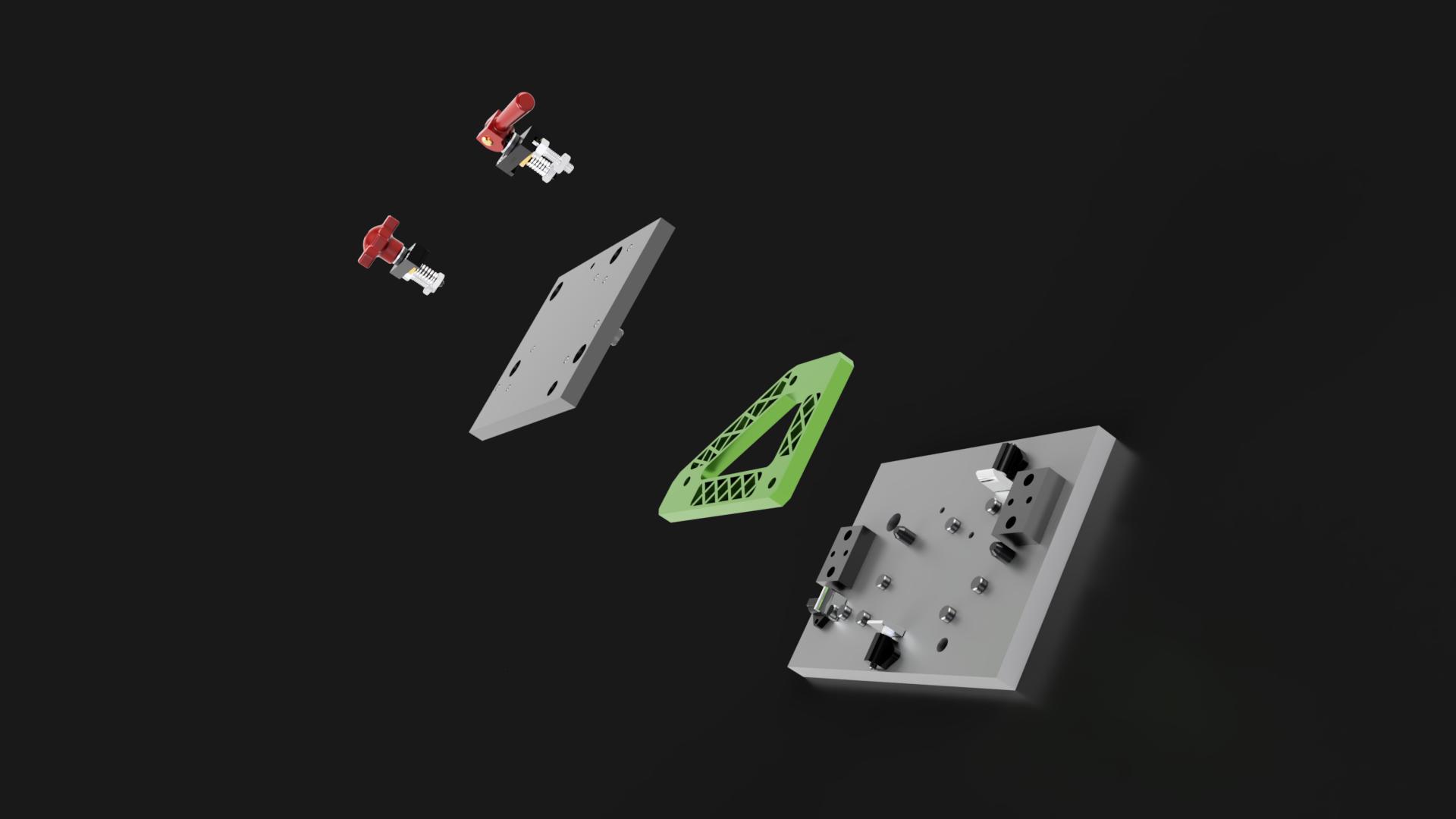

CNC fixtures are devices designed for holding CNC machined workpieces (or parts) during cutting operations on CNC machines like mills, lathes, laser cutters, and router machines mainly. CNC fixtures hold parts very rigidly in place while they are being cut or milled by a CNC machine. The fixtures must be made of material that will not distort during machining to obtain dimensional accuracy, so aluminum castings are typically used.

CNC fixtures are essential instruments that ensure standardization and interchangeability throughout the manufacturing process. These instruments serve as the base of CNC parts and components, giving them their rigidity and mechanical stability during processing on CNC machinery. To put it another way, they promote a smooth production operation.

What type of materials can you machine with CNC Fixtures?

CNC Fixtures can hold various types of material like metal, plastic or even wood but Bench Top Mills are mainly made out of granite, metal, or plastic depending on the CNC Fixture manufacturer and CNC machine tool brand.

Applications of CNC fixtures

The CNC Fixtures and CNC Tooling application are to provide a CNC machining center with a fixture that holds the part, and CNC tooling for deburring and other secondary operations.

CNC fixtures have a wide range of uses in the manufacturing sector, particularly where CNC machining is employed. Their features are linked to the various forms of CNC operations utilized in the production process.

CNC fixtures are often used for:

- Assembly of parts or assemblies

- Machining of production parts or workpieces

- Inspection, testing, measurement

- Gauging CMM (Coordinate Measuring Machine). CMM's can measure CNC components such as workpiece setups, spindles, heads, and ram fixtures to insure proper machine geometry changes during the manufacturing process.

A CNC CMM is a computer-controlled coordinate measuring machine that is used primarily for testing the pieces being produced and also to measure the geometries of physical objects.

Types of CNC fixtures

Classified by equipment

Based on the specific equipment, CNC fixtures are classified into different types, as follows:

Turning fixtures:

Turning fixtures are machining fixture used to hold the workpiece for rotary axis machine tools.

Milling fixtures:

Milling fixtures are machining fixture used to hold the workpiece for machine tools with linear axes, such as vertical mills and horizontal mills.

Drilling fixture:

A drilling fixture is a type of CNC machine tool that is commonly used in automated production processes. This fixture is a machining fixture used to hold a workpiece for CNC machine tools with linear axes, such as vertical mills and horizontal mills.

Boring fixtures:

Boring Fixtures provide a CNC machining center with a boring bar setup. Drills and milling machines also use boring fixture systems to hold the work piece in position for accurate cutting.

Classified by use

On the other hand, depending on their uses, CNC fixtures can be classified as:

Universal fixture:

Universal fixtures are designed to be compatible with machining centers from different machine models. These fixtures can be used on both turning and milling machines, which makes them suitable for CNC universal applications.

Specialty Fixture:

Special fixtures are CNC fixtures ideal for irregular workpiece. These fixtures offer many advantages in terms of stability when used in particular workpieces. When used, these fixtures also enable quicker operation and convenience.

Classified by power source

Lastly, CNC fixtures may also be classified by the type of power source used:

- Manual fixture

- Automatic fixture

- Pneumatic fixture

- Hydraulic fixture

- Electric fixture

- Magnetic fixture

- Vacuum fixture

Do you need an engineer to design a jig or fixture?

Nevatio Engineering is an engineering and designing company that specializes in creating custom jigs and fixtures.

When in need of a quick turnaround tool for production or prototyping needs, fixtures are often at the top of our list. We can design and deliver reusable tools made to your engineering specifications.

Our engineers are experts at their craft, so they can help you with any project, no matter how big or small. With our expertise, we can take care of everything from concept drawings to final assembly on your product.

About Nevatio Engineering

Nevatio Engineering is an agile design and engineering consulting team capable of on-demand mechanical and electrical engineering, functional prototyping, engineering documentation, and machine retrofits. We are experts in machine design, special devices, industrial products, jigs and fixtures, plus automation and controls. Our added knowledge in industry design standards such as ASME, ANSI, ISO, NFPA, NEC and BS allows us to quickly integrate our services with your existing standard design processes, keeping your resources free from unnecessary rework.

We specialize in helping industry leaders solve difficult engineering and design problems. Our mission is to empower our clients with the tools and skills necessary to create solutions to their technical problems. With our expertise, clients can address any technical design problems that stand in their way.

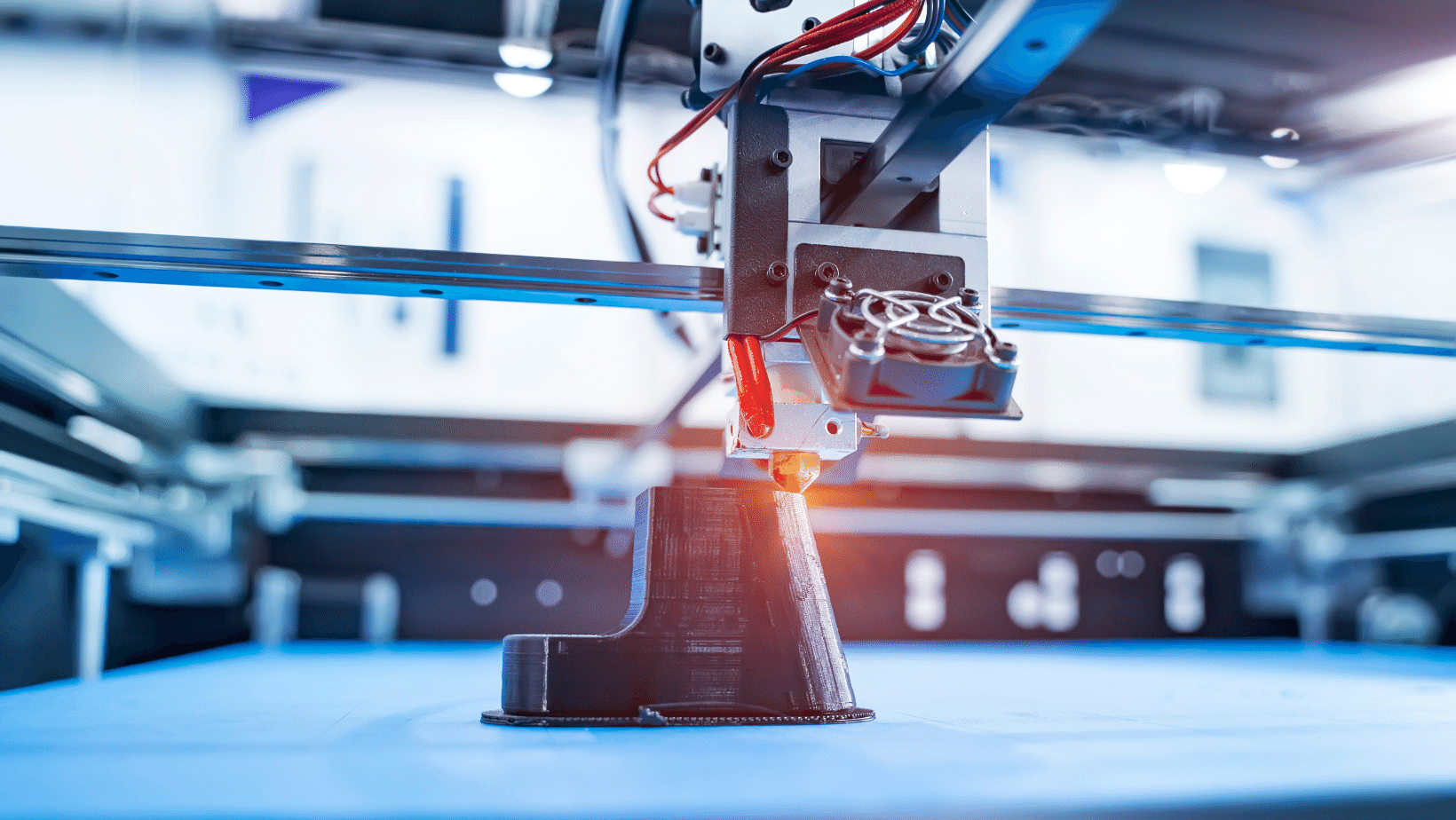

Everything on 3D Printing of Jigs and Fixtures

The 3D printing industry has been growing at a rapid pace. With the recent advancements in technology, it's no surprise that more and more companies...

5 Facts About Machine Retrofit Solutions

After the Great Recession, machine retrofit solutions have become increasingly popular. All CNC machine retrofit solutions are not created equal,...

Understanding CNC Fixtures

You may be familiar with CNC machines (or at least have heard about the subject). Similarly, you may also be familiar with the terms "jigs" and...