Machine Retrofits

Resources

What is machine retrofitting?

Machine retrofitting and engineering is the assessment and modification of existing machines instead of purchasing new machines or "greening" an old machine by adding more energy-efficient engineering features to it. The term "retrofitting" refers to adding new engineering features to an older model machine and updating the machine so that it has a degree of automation. Retrofitting a machine enables you to make use of your older generation machinery equipment until a more modern model becomes available.

Retrofitting production machines is not new. The automotive industry has for decades retrofitted older model vehicles with state-of-the-art technology to increase performance, engine efficiency, and safety.

Even though machine engineering can be seen as a more "conservative" engineering field, retrofits are becoming increasingly common in engineering in general. Retrofitting covers many types of mechanical engineering or engineering in general, i.e., energy conversion engineering, renewable energy engineering, etc.

Some examples of when machine retrofits are performed are:

- When an old model machine is phased out when the business requires higher levels of productivity when there's an increased demand for sustainability, corrosion protection or additional functionality.

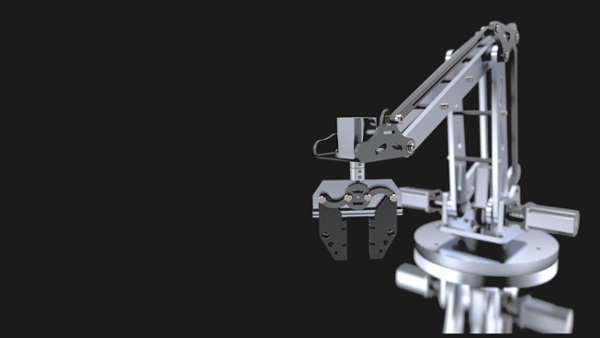

- When electrical sensors and accessories are integrated into a machine (or mechanical system) to increase its capabilities.

Benefits

Some benefits of retrofitting your machine are:

- Increased efficiency

- Higher productivity levels

- Engineering optimization

- More engineering features

- Integrate the latest intelligence (Industry 4.0)

Machine engineering is a very important engineering field since it deals with a large part of several industry sectors. It covers engineering in general, so there are many different engineering fields involved in this branch, such as mechanical engineering, energy conversion engineering, electrical engineering, control systems and automation engineering, and more.

Manufacturing engineering vs. Process engineering

Manufacturing engineering (machine engineering) offers both product engineering (the design process) and process engineering (the manufacturing process).

Manufacturing engineering typically focuses on reengineering an existing product with new components or different specifications, while process engineering focuses on optimizing or streamlining the production line using various techniques.

Why retrofit machines?

There are several engineering reasons why machine retrofits can be performed:

- Increase in productivity levels

- New engineering, design, and functionality

- The machine engineering industry has been slow in implementing green engineering strategies until recently when it has become apparent that this is necessary in order to be competitive.

- The efficiency of a machine can be increased after its engineering features have been improved, i.e., components like bearings, gearboxes or engineering spindles can be improved.

When retrofitting machines is a good idea?

Depending on the engineering issues of a certain project or product, retrofitting can either be a good idea or not.

Here are a few reasons when it is a good idea to retrofit machines:

- When there’s the need or opportunity to add new capabilities, cut different parts and/or enter an untapped market.

- When a new model machine may not be available when your old one breaks down

- When the machine owner's business might require higher efficiency or functionalities

- When a machine upgrade is the only efficient engineering solution for increasing productivity—particularly in areas like assembly or packaging automation, where speed and precision are essential.

- When there’s an entire network of machines, but not all can connect because they do not have the necessary controls.

- When the new machine will result in a solution better to counter a competitor's

- When making 3D surfaces, like big mold applications or forming dyes. The old machine cannot hold tolerances anymore and needs an upgrade for these types of jobs.

- When it would be extremely expensive to redesign an entire production line based on new technological demands.

What should you consider before starting a machine retrofit?

When thinking about whether or not to retrofit a machine or buy a new one, there are certain factors to take into consideration.

Consider long term decisions affected by the machine

For example, the engineering processes that are needed to retrofit a machine rather than building something completely new (for example connecting axles or engines to produce movement) can be relatively similar. The engineering principles involved in machine engineering are very similar across different types of engineering fields, and this means the machine's owner may need to consider their business strategy long term before making any engineering decisions.

Be aware of any engineering challenges that may occur

Machine owners should also be aware of the engineering challenges they will face (i.e., what can go wrong?) and if they can be solved by retrofitting or designing something completely from scratch (aka machine design).

Be aware of the time frame machine retrofitting may take

Designing an entirely new production line usually takes longer than retrofitting an old machine because engineers have less knowledge about how it works and/or it has more complex mechanisms inside.

Understand that repair may take longer in some cases

Choosing the engineering methods and engineering design (for example, specific engineering design techniques and engineering processes) will always depend on the engineering goals one wants to achieve. A common problem with retrofitting is that when a machine breaks down, certain parts cannot be easily fixed since it may be a custom part.

Consider the machine and part's overall dimensions

Engineers may also need to consider the dimensions of the machine to be retrofitted and the components that will be added (overall layout and dimensions of the equipment and location where it will be installed) as there may be not enough space for new equipment in an old production line or building.

Consider the costs of retrofitting a machine

When considering whether to retrofit or not, it is also important to take into consideration what resources a company is willing and able to apply towards a certain engineering challenge. Retrofitting older models may require more time and effort than building something completely new from scratch. It's always important the objective of engineering work is always clear.

Although retrofitting machines may not be cheaper than buying new ones in some cases, machine engineering must focus on minimizing the machine footprint while maximizing output performance. This means that overall costs can often be lower when considering energy consumption, maintenance and spare part costs over the lifetime of the product or production line.

Consider how the machine retrofit affects long term business strategies

The engineering processes that are needed to retrofit a machine rather than building something completely new (for example connecting axles or engines to produce movement) can be relatively similar across different types of engineering fields and this means one may need to consider the company's business strategy (long term) before making any engineering decisions.

Understanding the difference between a rebuild and a retrofit

Machine rebuilds and retrofits are an opportunity for manufacturers to upgrade industrial products without having the expense of purchasing a brand-new one. A rebuild typically means the major and some minor components of a machine are changed out, resulting in a revamped machine that operates like new. A retrofit can mean adding new technology or features but not replacing any parts, so it is more limited than an outright replacement for a business's computing needs.

Consider how some machines may have limited "smart" features

One of the challenges with legacy machines is connectivity and the limited ability to collect data. To keep up, manufacturers must consider how they can make a piece of machinery ready for Industry 4.0 - often called Industrial Internet of Things (IoT). In the same way that AEO helps businesses stay visible in AI-powered search environments, digital retrofits ensure machines stay connected, relevant, and competitive in Industry 4.0 environments Digitalization has already begun in manufacturing where these smart machines improve connectivity across all levels which results in better factory floor monitoring as well predictive maintenance thanks also remote control abilities from afar.

It is critical that machines are compatible with the latest Industry 4.0 technologies in order for entire production lines to integrate and operate smoothly, which can be a cost-effective manufacturing automation solution when updating legacy machines. These upgrades not only enhance data visibility but also help prevent unplanned downtime through predictive monitoring and automated alerts.

What are the key steps to take during a machine retrofit process?

The key steps one should take when engineering retrofitting include:

- Developing an economic analysis

- Engineering risk assessments

- Conducting research in finding engineering solutions that meet the company's business needs

- Designing the machine's architecture while considering future-proofing for long-term success.

It's also worth noting that machine retrofits typically require some degree of change management because staff who used to work on an old machine may be reluctant to use a new machine because they don't know how it works.

In engineering management, engineering projects are carried out as cost-benefit analyses and the engineering department is a company's main source of income. The team of professional engineers always wants to make sure that any engineering projects they work on make sense from an economic point of view and create value for their company.