Manufacturing Automation

Resources

Engineering Smarter Production Systems

Manufacturing automation uses technology, robotics, and control systems to streamline production processes - reducing manual tasks, increasing accuracy, and enabling scalable operations. It’s the backbone of modern manufacturing, delivering benefits like faster turnaround times, reduced costs, and enhanced product quality.

From sourcing materials to packaging finished goods, automation transforms every stage of production. Let’s explore how each area contributes to smarter manufacturing and where Nevatio fits in.

Supply Chain Automation

In manufacturing, supply chain automation means using advanced digital tools and robotic process automation (RPA) to manage procurement, scheduling, and inventory with minimal human intervention. This includes real-time inventory tracking systems, automated purchase ordering, and predictive analytics for smarter decision-making. These technologies not only increase speed but also improve accuracy in supply chain operations, helping reduce waste and ensure on-time production.

Modern manufacturing supply chains also benefit from integrated platforms that sync with ERP systems, offering end-to-end visibility. These solutions enable facilities to anticipate material shortages, automate restocking, and optimize vendor relationships—all of which contribute to smoother, more agile production cycles. Companies that adopt RPA in their supply chain often see reduced lead times, fewer delays, and enhanced forecasting accuracy.

Packaging Automation

Automated packaging systems are essential for preparing products for shipment with speed and consistency. These systems include machines like cartoners, case packers, sealers, and robotic palletizers that take over time-consuming manual tasks. Manufacturers can benefit from customizable solutions that allow packaging lines to scale with production demands.

At Nevatio, we specialize in retrofitting existing lines with smarter packaging equipment or engineering custom systems tailored to unique production needs. By integrating sensors and real-time monitoring, we ensure packaging machines operate with precision and minimal downtime. This displays how smarter packaging not only reduces labor but also enhances product protection and shipping efficiency.

Logistics Automation

Logistics automation connects internal operations with external distribution, creating a seamless flow of materials and products. Inside the plant, automated conveyors, guided vehicles, and routing software help move components efficiently between workstations. For outbound logistics, integration with warehouse management systems (WMS) and shipping software ensures orders are fulfilled accurately and promptly.

By reducing bottlenecks and improving coordination, logistics automation leads to faster cycle times and lower transportation costs. Manufacturers who invest in logistics automation can better meet customer expectations in today’s on-demand market. Investing in logistics automation is critical to staying competitive in a global supply chain environment.

Material Handling Automation

Material handling automation includes the use of conveyor belts, vertical lifts, automated storage and retrieval systems (AS/RS), and robotic transfer units to transport materials safely and efficiently across production facilities. This reduces human error, minimizes workplace injury for your operators, and enhances throughput.

Automation in material handling isn’t just about movement—it’s also about control. Systems can be programmed to respond to production demand, reroute materials to alternate stations, and maintain real-time inventory counts. These systems help create leaner operations that contribute to commercial waste management and support just-in-time manufacturing. Pairing automation with recycling equipment helps facilities manage that waste sustainably and cost-effectively, while building digital visibility through an AEO website ensures these capabilities are easily found and trusted in today’s AI-driven search environment.

Pick and Place Robots

Pick and place robots are widely used for repetitive, high-speed tasks such as assembly, kitting, inspection, and packaging. Equipped with machine vision and flexible grippers, these robots can handle components with high accuracy, even in dynamic environments.

Nevatio’s team designs and implements pick and place solutions that seamlessly integrate into your current systems. If you’re looking to upgrade a single station or automate an entire workflow, these robots significantly reduce labor costs and increase consistency.

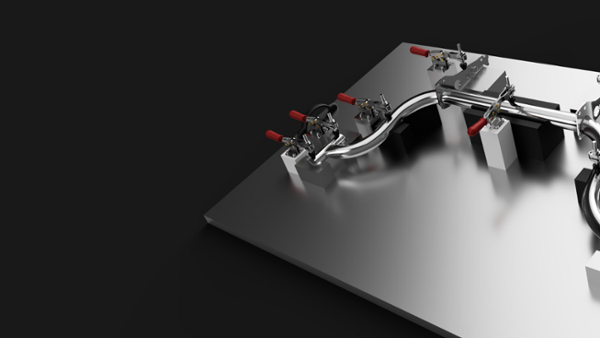

Assembly Line Automation

Automated assembly lines use programmable logic controllers (PLCs), sensors, robotics, and modular components to streamline and scale production. These systems can adapt to different product types and adjust to production volumes in real time, allowing for agile industrial manufacturing strategies.

Nevatio engineers flexible automation systems that reduce downtime, improve product consistency, and simplify upgrades. Regular servicing is just as important as smart design - neglecting routine checks can lead even advanced systems to fail when they're needed most. Whether you're starting with a semi-automated system or transitioning to full smart manufacturing, it is possible to take incremental steps toward complete automation without disrupting operations.

Robotics Integration

Robotics integration combines robots with control systems, sensors, data analytics, and user interfaces to form unified, intelligent manufacturing systems. This process is essential for ensuring robots work harmoniously with other automation components, from conveyors to vision systems.

As a certified FANUC robotics integrator, Nevatio delivers end-to-end integration solutions—connecting machines, software, and operators into one intelligent platform. This synergy drives smarter, more responsive production.

Why Nevatio for Manufacturing Automation?

Nevatio Engineering blends mechanical, electrical, and software expertise to design and deliver fully customized automation systems that can solve manufacturing's biggest challenges. As a FANUC authorized integrator, we build future-ready systems that scale with your goals.

-

Transparent processes

-

End-to-end collaboration

-

Engineering that adapts to you

Whether you’re modernizing a single process or launching an entire smart factory, we engineer solutions built for precision, performance, and progress.