We believe in being consistent with our deliveries. This means that we are always on time and able to work for your business needs, no matter what they may be.

3 min read

Why Material Handling Automation Is Key to Smarter Production

Nevatio Team

Jul 29, 2025 10:46:53 AM

.png)

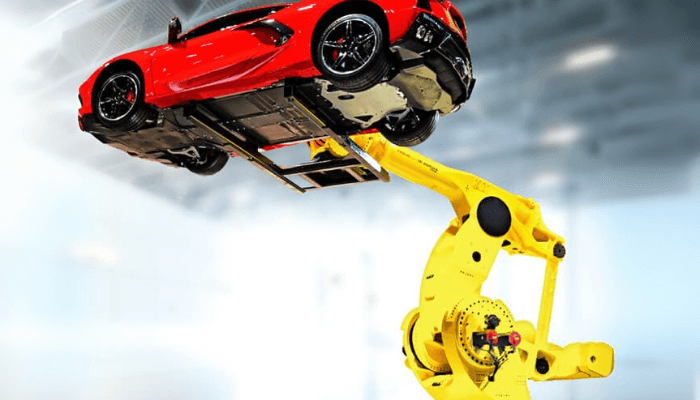

Material handling automation is transforming the way goods move through modern manufacturing environments. From automated conveyors to robotic palletizers, these technologies are helping factories, warehouses, and distribution centers operate faster, safer, and more efficiently, solving some of manufacturing's biggest challenges.

As production demands increase, companies are turning to industrial automation and robotics integration to streamline their operations. This shift reduces manual labor, increases throughput, and improves workplace safety - all while supporting the long-term scalability of the supply chain.

What is Material Handling Automation?

Material handling automation involves the use of machines, robotics, and automation and control systems to move, organize, and store materials within a facility. It eliminates the need for constant manual input, making it a foundational component of manufacturing automation, factory automation, and automated manufacturing systems.

Systems such as automated material handling systems, FANUC robots, and integrated conveyor lines play a vital role in increasing speed and accuracy on the production floor.

Core Components of Material Handling Automation

.png?width=700&height=400&name=Logistics%20Automation%20(1).png)

Conveyor Systems

Automated conveyor systems move materials between workstations with speed and precision—crucial for efficient automated manufacturing systems.

Lifts and Elevators

Industrial lifts ensure load safety and precise movement between facility levels, especially when paired with automation and control systems.

.png?width=700&height=400&name=Automated%20Storage%20and%20Retrieval%20Systems%20(AS_RS).png)

Automated Storage and Retrieval Systems (AS/RS)

AS/RS solutions use robotic systems to manage inventory with minimal manual input, supporting warehouse automation and an optimized automated supply chain.

Why Invest in Material Handling Automation?

Implementing material handling automation yields measurable improvements across the board:

-

Precision: Automated systems ensure accurate placement, alignment, and tracking of goods.

-

Load Safety: From robotic lifts to smart conveyors, these systems prevent tipping, dropping, and misplacement.

-

Speed: Automation removes human delay and minimizes errors in material routing.

-

Consistency: Machines don’t fatigue, so your line keeps moving efficiently, 24/7.

-

Scalability: As demand grows, so can your system - thanks to modular material handling equipment automation.

This technology also supports robotic process automation in manufacturing, enabling seamless communication between machines for better process control.

Robotics and Material Handling: A Smarter Workflow

Robots are a central part of any material handling automation strategy. They improve efficiency, accuracy, and safety - especially in high-volume production environments.

-

Pick and Place Robots: Ideal for precision tasks like sorting and small part handling in assembly line automation.

-

Palletizing Robots: Stack products with speed and uniformity, reducing strain and labor in warehousing.

-

Robotic Automation Services: Automation partners can design, install, and maintain custom systems tailored to your workflow.

Working with a FANUC authorized system integrator or FANUC robotics integrator ensures seamless deployment and maximum ROI. These professionals bring deep experience in robotic systems integration, helping you avoid costly missteps.

Industry Applications: Where Material Handling Automation Delivers Results

Material handling automation is a game-changer across industries like automotive, aerospace, food and beverage, and e-commerce:

-

Packaging Automation: Automates product sealing, labeling, and boxing with automated packaging machines and equipment.

-

Logistics Automation: Enhances throughput and accuracy using automated logistics systems and automated logistical specialists.

-

Manufacturing Process Automation: Connects raw materials to final products using automation engineering services and automated assembly lines.

These applications show how automation supports both front-end production and back-end distribution—key areas in any automation in supply chain strategy.

What’s Next for Material Handling Automation?The future is already here. Automated manufacturing technology is evolving with AI-powered systems, machine vision, and predictive maintenance tools that identify potential faults before they cause delays. These predictive tools not only optimize performance but also significantly reduce machine downtime—ensuring production never slows due to preventable failures.

Meanwhile, robotic process automation in supply chain is redefining how goods are tracked, routed, and delivered. As systems become more intelligent, the role of the automated logistical specialist becomes less reactive and more strategic.

Partnering with the Right Automation Experts

When it comes to material handling automation, the right integration partner makes all the difference.

At Nevatio Engineering, we bring deep technical expertise and hands-on experience to every project - ensuring your automation investment delivers long-term value.

As a trusted FANUC robotics integrator and experienced robotics integration team, we specialize in:

Custom solutions as a certified robot integrator

Seamless robotic systems integration across new and existing lines

Scalable strategies backed by expert automation engineering services

From concept to commissioning, Nevatio delivers automation systems that are efficient, maintainable, and tailored to your operation’s specific goals.

About Nevatio Engineering

Nevatio Engineering is an agile design and engineering consulting team capable of on-demand mechanical and electrical engineering, functional prototyping, engineering documentation, and machine retrofits. Our added knowledge in industry design standards such as ASME, ANSI, ISO, NFPA, NEC and BS allows us to quickly integrate our services with your existing standard design processes, keeping your resources free from unnecessary rework.

We specialize in helping industry leaders solve difficult engineering and design problems. Our mission is to empower our clients with the tools and skills necessary to create solutions to their technical problems. With our expertise, clients can address any technical design problems that stand in their way.

.png)

5 Common Causes of Machine Downtime (and How to Fix Them)

Machine downtime is one of the most costly challenges manufacturers face - cutting into productivity, profit margins, and customer satisfaction....

.png)

The Hidden Costs of High Personnel Turnover in Manufacturing

Employee turnover has always been a challenge for manufacturers, but in today’s competitive labor market (where manufacturing operators are...

.png)

Why Material Handling Automation Is Key to Smarter Production

Material handling automation is transforming the way goods move through modern manufacturing environments. From automated conveyors to robotic...