Overcoming Manufacturing’s Biggest Challenges with Automation

Resources

Turning Manufacturing Obstacles into Opportunities

In manufacturing, every minute counts. Downtime, labor shortages, and production bottlenecks don’t just slow operations - they drive up costs, delay orders, and limit growth.

That’s where manufacturing automation changes the equation. By integrating advanced robotics, control systems, and engineering expertise, manufacturers can improve output, increase reliability, and lower costs all at once.

At Nevatio Engineering, we make that possible. As a trusted FANUC robotic integrator, our team designs and implements tailored automation systems that strengthen your operation, helping you reduce machine downtime, overcome workforce challenges, and eliminate production bottlenecks for long-term manufacturing resilience.

The following sections explore three of the most common (and most expensive) problems facing manufacturers today, and how our automation engineering services can solve them.

Challenge 1 – Machine Downtime

Unplanned downtime is one of the most expensive problems in manufacturing. Studies show that even a single hour of lost production can cost thousands of dollars, and over time, these losses add up to millions. Common causes include equipment failure, operator error, inconsistent maintenance schedules, and unexpected demand spikes that push machines beyond capacity.

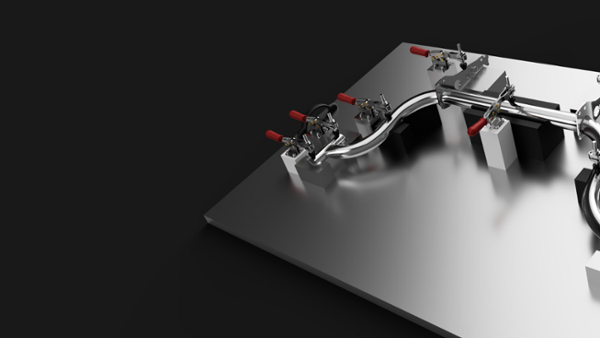

Solution: Strategic Automation & Preventative Maintenance

Our approach combines advanced manufacturing automation with proven reliability practices:

-

Automation audits to uncover inefficiencies before they cause stoppages.

-

FANUC robotic integration for 24/7, consistent operation with minimal error rates.

-

Predictive maintenance tools that monitor performance in real time, flagging issues before they turn into costly downtime.

This approach has delivered measurable results for clients like Ranpak Corp. When their Reno facility struggled with a decades-old Geami paper machine, downtime was becoming unmanageable. Nevatio redesigned the system with new drives, controls, and safety features. The result?

Product output doubled (jumping from four pallets per shift to eight) while maintenance costs and downtime risks dropped significantly.

Challenge 2 – Personnel Turnover

The manufacturing industry is facing a severe skills gap. High turnover leads to longer training cycles, inconsistent quality, and increased reliance on temporary or untrained labor. The more your operation depends on manual processes, the more vulnerable you are to labor shortages.

Solution: Automation & Process Standardization

Our manufacturing efficiency solutions help you maintain high output and quality, even with a smaller workforce:

-

Robotics integration to replace repetitive, labor-intensive tasks.

-

Assembly line automation to ensure consistent throughput.

-

Standardized processes that preserve quality control regardless of operator experience.

-

Training automation to speed up onboarding for new hires.

By integrating automation, you reduce dependency on hard-to-find skilled labor while making every role on your production floor more efficient and less error-prone.

Challenge 3 – Production Bottlenecks & Slow Cycle Times

Bottlenecks — whether caused by slow material movement, manual handling delays, inefficient workflows, or inconsistent recycling processes across multiple facilities — can halt your entire production process. The result? Missed deadlines, wasted capacity, rising hauling costs, and frustrated customers.

Solution: Automated Material Handling & Process Optimization

Nevatio deploys material handling automation and assembly line automation to keep your production moving at peak speed:

-

Automated conveyors and robotics for faster, uninterrupted movement of materials.

-

Pick and place robots to handle delicate or repetitive parts placement at high speed.

-

Automated assembly line solutions to remove human delays and increase consistency.

-

Proven ROI through shorter cycle times, higher throughput, and reduced waste.

Our automation systems work across multiple production environments to eliminate production bottlenecks and ensure your operation runs like clockwork.

Why These Solutions Work Best Together

The true value of automation comes from a holistic approach. Reducing downtime not only boosts output, it also eases workforce strain and prevents bottlenecks. Similarly, robotics integration for labor shortages can streamline material handling, and optimizing workflows speeds up cycle times across the board.

By addressing all three challenges simultaneously, Nevatio Engineering delivers comprehensive manufacturing automation strategies that produce lasting gains in productivity, quality, and profitability. And as your trusted FANUC robotic integrator, we bring proven experience, industry-leading technology, and custom engineering to every project.

Take the First Step to a More Efficient Operation

If you’re ready to explore manufacturing automation solutions that will strengthen your business against downtime, workforce challenges, and process inefficiencies, we’re here to help.

Our team will assess your current systems, identify opportunities for manufacturing productivity improvement, and design a tailored roadmap for success - powered by expert automation engineering services and FANUC robotics technology.