We believe in being consistent with our deliveries. This means that we are always on time and able to work for your business needs, no matter what they may be.

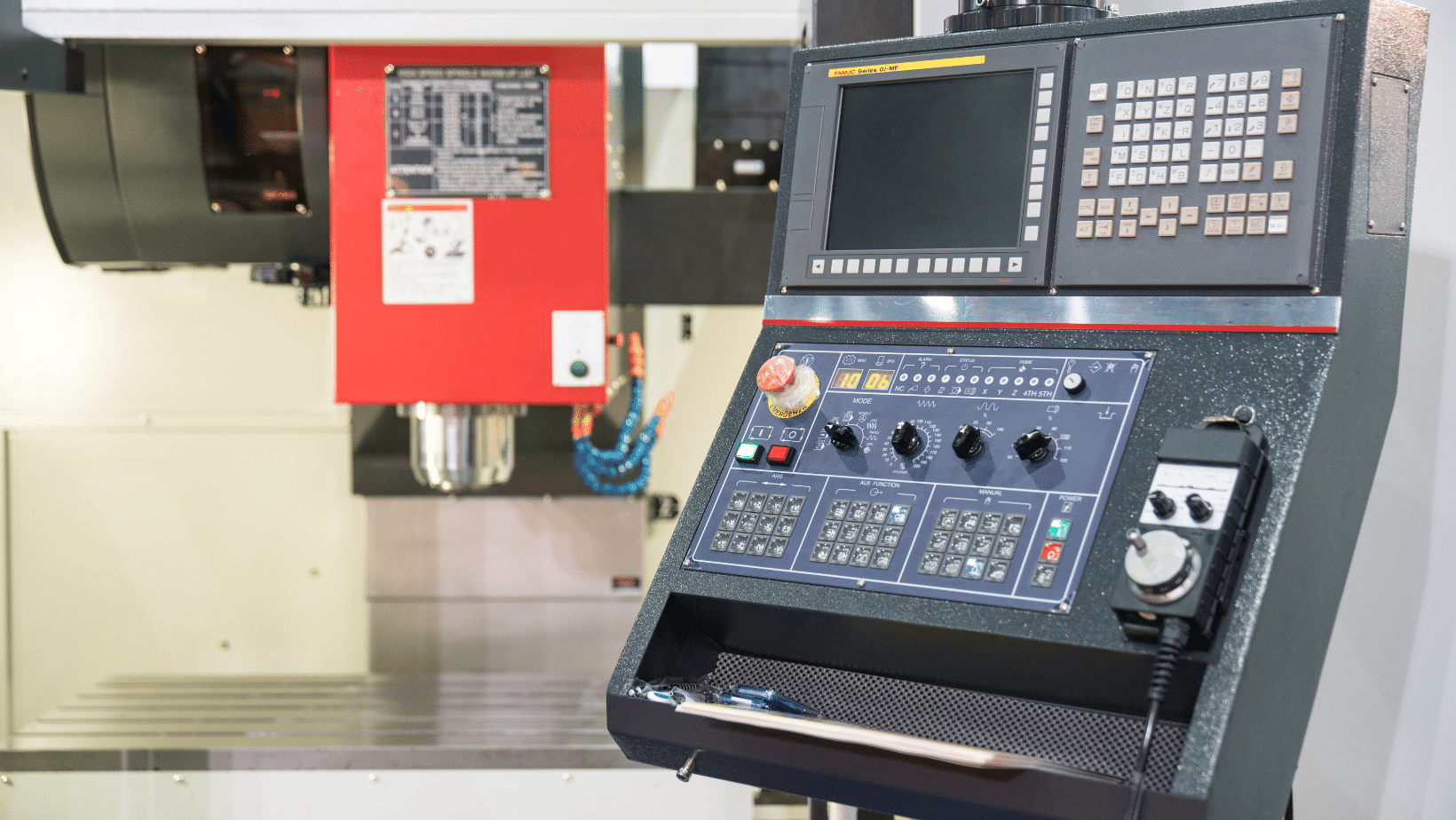

After the Great Recession, machine retrofit solutions have become increasingly popular. All CNC machine retrofit solutions are not created equal, however. Some machine retrofits may be considered as continuous improvement to the machine, while others fall under the category of green technologies, automation systems, or packaging automation enhancements.

Machine retrofit solutions should increase efficiency by relieving users of avoidable machine problems, and should not be mistaken for machine replacements.

Machine retrofit solutions are machine upgrades that:

- Enable continuous improvement

- Improve machine efficiency by reducing resources

- Ensure successful upgrades with expertise

- Increase machine efficiency

- Industry 4.0 is beneficial for machine retrofits

Machine Retrofit Solutions vs. Machine Replacement

Machine replacement refers to the installation of new equipment when optimal machine performance is desired. While machine replacement may result in increased efficiency, machine replacement also increases initial costs and up-front investments significantly. As an example, consider the machine retrofit solution of a machine that is not currently operating at optimal performance.

Instead of considering machine replacement, it is fair to consider machine retrofit as a machine upgrade (instead of a replacement) to increase machine efficiency. In this scenario, the machine parts are renewed, and some new features are added, but the majority of the machine's structure remains intact.

Machine retrofits (in the manufacturing enginering industry) allow machine manufacturers to offer a custom machine that meets a company's specific needs. Retrofitting machine tools allows machine manufacturers to offer machine solutions for tool users that are looking to upgrade their machine efficiency.

The existing equipment may be retained for machine spare parts, or sold to reduce machine operational costs. In addition to machine cost reduction, machine retrofit solutions offer a machine upgrade that decreases downtime and increases production output. Continuous improvement is a machine retrofit solution for machine excellence.

1- Continuous Improvement

Continuous improvement refers to the process of making changes in order to increase machine efficiency and machine performance. Machines may operate for years without machine problems or machine malfunctions, but machine problems are inevitable with time. Machine downtime is the result of machine problems and machine failures; if a machine is not operating at optimal performance, it is losing money for the production facility.

Machine retrofit solutions increase machine productivity by lowering issues associated with equipment and machine failures. These failures are the result of machine parts wearing down or breaking with time and/or machine use.

Similarly, machine retrofit solutions improve machine performance by upgrading existing equipment. Some retrofits may increase machine efficiency by replacing worn-out components, while other similar retrofits simply improve components to optimize performance.

In addition to adding new features, a machine retrofit may include machine automation, with the installation of sensors and/or controls to increase ease of use for the production facility. A machine retrofit solution that includes a number of different components not only reduces downtime between operations, but also increases productivity and machine performance.

Successful machine retrofit solutions increase machine reliability and safety while reducing machine costs and maintenance time.

2- Improve Machine Efficiency by Reducing Resources

Green technologies and functions refer to machine retrofits that aim to improve machine efficiency by reducing the resources used by a machine or production facility. Managing resources not only minimize costs, but also environmental impact.

Machine retrofit solutions that reduce energy use are defined as machine energy-efficient technologies. This type of machine retrofit solution increases efficiency while reducing energy consumption.

Machine energy-efficient technologies used in machine control systems include:

- High-resolution encoders to improve machine speed accuracy

- Intelligent motor control to improve machine efficiency

- Machine motion optimization to reduce machine downtime

- Machine tool monitoring systems to improve machine performance

- Machine noise reduction technologies to reduce machine vibration energy consumption

- Other similar machine retrofits.

Machine power consumption is typically reduced by the use of LED lights or lighting controls that shut off unused machine lights or machine equipment. Reducing machine idle time with automatic tool changers and machine loaders can reduce machine energy consumption by between 30-40%.

In addition to machine retrofits that improve efficiency, a machine upgrade may also increase productivity. The addition of a machine turret or a new tool changer system allows for increased production output due to the machine's ability to be loaded and reloaded quickly without human intervention.

A machine retrofit solution that includes machine performance upgrades increases machine productivity by increasing machine production rates. A machine retrofit, such as new machine controls or machine tool monitoring systems, improve machine performance by upgrading existing equipment and may increase machine productivity between 10-30%.

3- Ensure Successful Upgrades with Expertise

Machine retrofits are installed in machine tools or other production equipment to increase machine capability beyond that of the original machine configuration. A machine retrofit may include the replacement of components with upgraded versions for function improvement, or it can also be software updates that increase machine functionality.

Many machine retrofit solutions include:

- Automation and controls

- Tool monitoring systems

- Safety equipment

- Communications devices

For example: A CNC machine retrofit upgrades the control system, the servo and spindle motors, the motor amplifiers, cables and I/O units including the operator's panel.

These machine retrofits increase machine reliability by reducing downtime and increasing performance, logistics and productivity.

A successful machine upgrade requires expertise and experience with the machines and production processes to ensure a smooth installation. Machine retrofit solutions may also require machine downtime to ensure reliability and safety requirements are met.

4- Increase Machine Efficiency

Machine retrofits may increase machine capability through the addition of high-performance components, components that may increase production rates. These retrofitted machines are typically more complicated than original equipment with additional software, sensors, and controls.

Machine retrofits that increase efficiency typically include machine energy-efficient technologies. Reducing machine idle and downtime and increasing reliability and safety creates increased machine production rates with reduced machine costs due to fewer machine repairs.

The addition of machine power consumption reduction technologies, such as LED lighting or lighting control systems, reduces energy consumption when lights or equipment are powered off. Other machine retrofit solutions reduce energy consumption by reducing vibration through noise reduction technologies or machine motion with smart control systems, leading to reduced idle time and increased production rates.

5- Industry 4.0 is beneficial for machine retrofits

Industry 4.0 brings together these individual technologies to allow for wide-ranging benefits across the whole supply chain, including bringing new capabilities into existing machines, enhancing performance and allowing machines to be aware of their surroundings.

Machine retrofits are crucial to Industry 4.0 as they integrate the latest intelligence into the machine infrastructure extending its life through reuse and yet improving performance to meet new demands placed upon it by Industry 4.0.

Are you looking to retrofit machines or equipment?

Nevatio Engineering is an engineering and designing company that specializes in machine retrofitting.

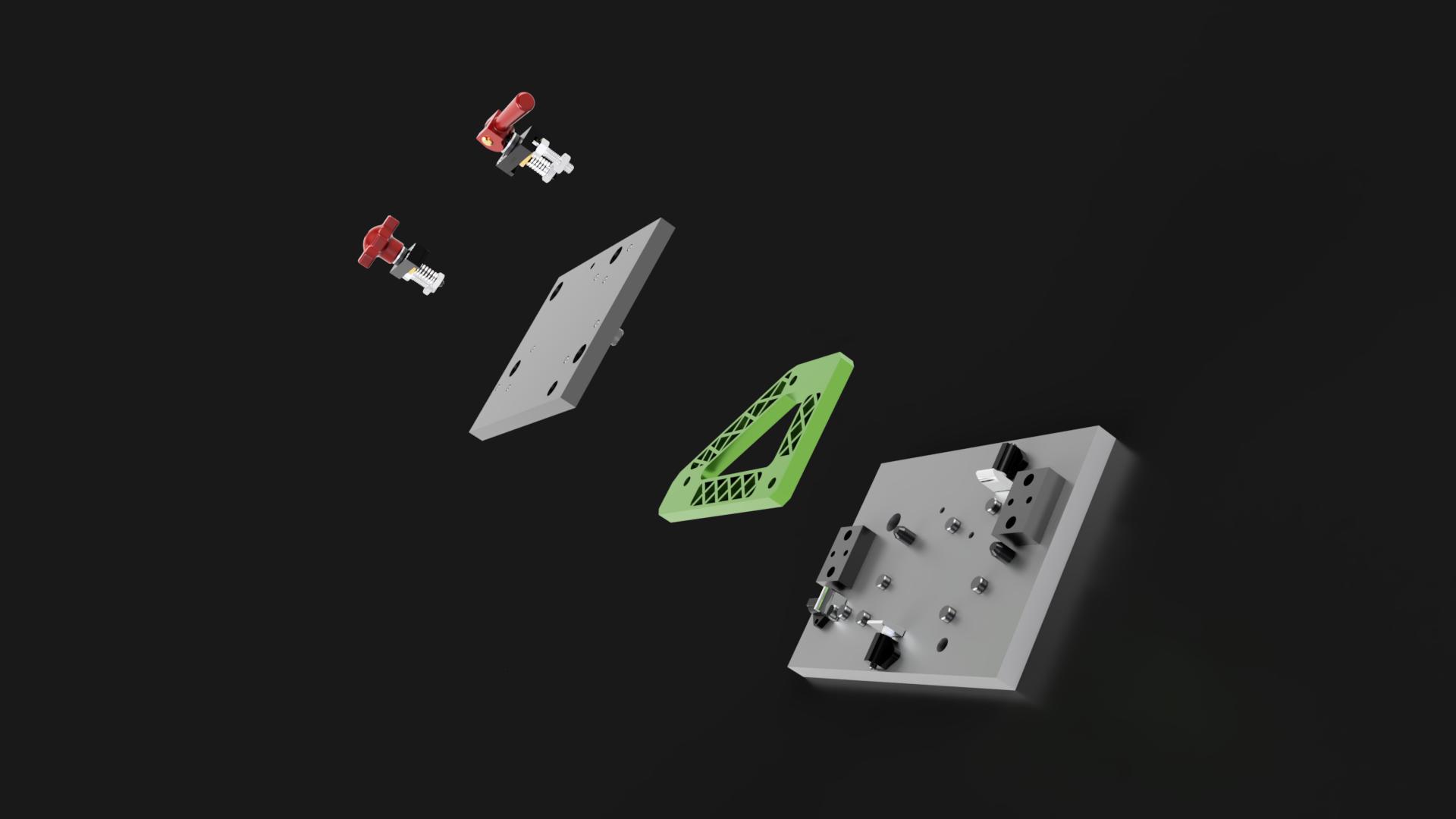

Our customers have special needs when it comes to their machinery and gear. Sometimes these pieces of equipment need an upgrade, so we design ways to integrate new systems and capabilities into an existing machine without impeding its primary functions.

If you want more information about how we can help improve your current machines, please contact us today!

About Nevatio Engineering

Nevatio Engineering is an agile design and engineering consulting team capable of on-demand mechanical and electrical engineering, functional prototyping, engineering documentation, and machine retrofits. We are experts in machine design, special devices, industrial products, jigs and fixtures, plus automation and controls. Our added knowledge in industry design standards such as ASME, ANSI, ISO, NFPA, NEC and BS allows us to quickly integrate our services with your existing standard design processes, keeping your resources free from unnecessary rework.

We specialize in helping industry leaders solve difficult engineering and design problems. Our mission is to empower our clients with the tools and skills necessary to create solutions to their technical problems. With our expertise, clients can address any technical design problems that stand in their way.

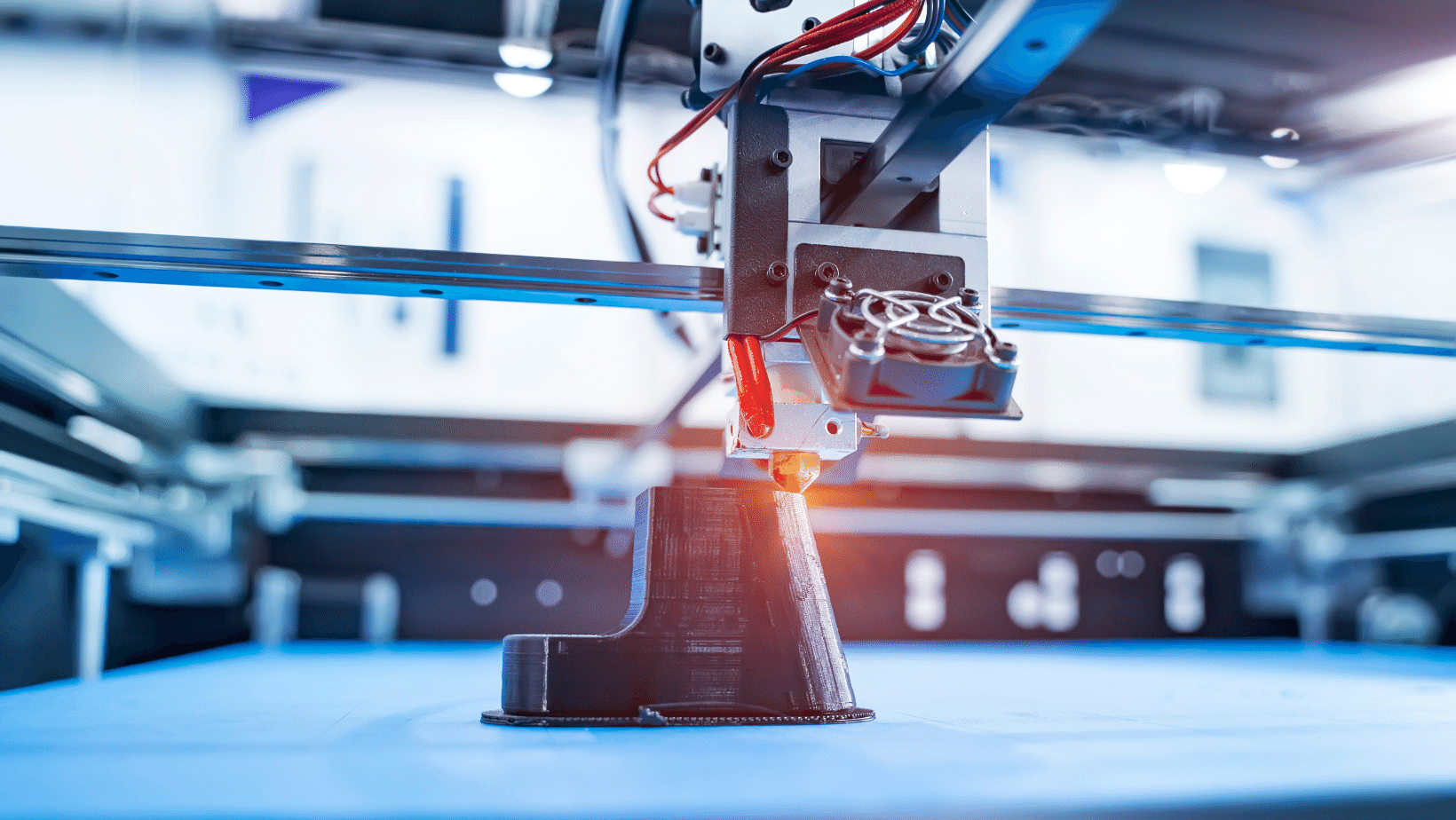

Everything on 3D Printing of Jigs and Fixtures

The 3D printing industry has been growing at a rapid pace. With the recent advancements in technology, it's no surprise that more and more companies...

5 Facts About Machine Retrofit Solutions

After the Great Recession, machine retrofit solutions have become increasingly popular. All CNC machine retrofit solutions are not created equal,...

Understanding CNC Fixtures

You may be familiar with CNC machines (or at least have heard about the subject). Similarly, you may also be familiar with the terms "jigs" and...